Category: Wrenches

The Best Adjustable Wrench of 2025The Best Adjustable Wrench of 2025

Adjustable wrenches are indispensable tools for professionals and DIY enthusiasts alike. Whether you’re a mechanic, plumber, or someone who enjoys home repairs, having the right adjustable wrench can significantly impact [...]

How to Use an Adjustable WrenchHow to Use an Adjustable Wrench

In the hand tool industry, an adjustable wrench is one of the important tools due to its versatility for fastening nuts and bolts. Whether you’re a DIY enthusiast or professional, [...]

Wrenches: The Ultimate Buyer’s Guide To Choose The Right OneWrenches: The Ultimate Buyer’s Guide To Choose The Right One

Whether you’re a professional mechanic or a DIY enthusiast, dealing with small home repairs and maintenance tasks is never easy. A wrench is such a versatile tool that comes in [...]

Spanners Vs Wrenches: What’s The Difference?Spanners Vs Wrenches: What’s The Difference?

Looking for an adjustable to loosen or tighten the nuts and bolts of your car? Or working on projects but don’t know which adjustable hand tool you have. Don’t worry! [...]

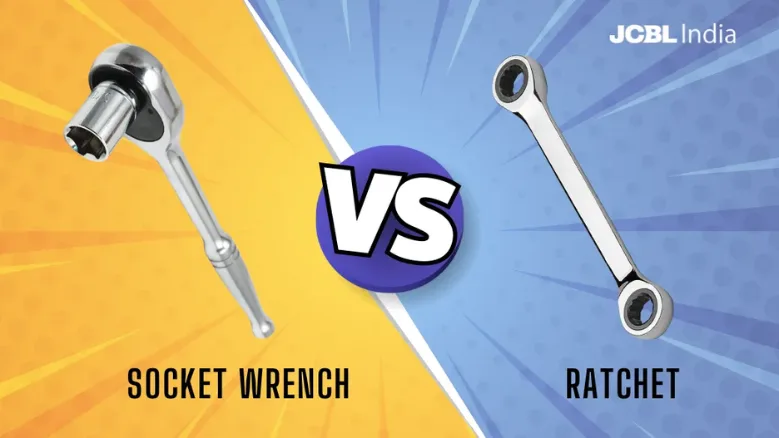

Socket Wrench Vs Ratchet: What is the Difference?Socket Wrench Vs Ratchet: What is the Difference?

In the world of hand tools, socket wrenches, and ratchet wrenches are indispensable for any mechanic, DIY enthusiast, or professional tradesperson. Understanding the differences between these two wrench tools can [...]