Hand Tools: Average Manufacturing Labor Cost India vs China 2026

If you are concerned with sourcing, importing, or manufacturing hand tools, then it is definitely among your initial concerns to evaluate. As the year 2026 draws near, this comparison will only become even more crucial as there is a heightened need and different manufacturing costs across different nations. One of the most searched and discussed topics today is the average manufacturing labor cost in India vs. China in 2026, especially for labor-intensive products like hand tools.

In this blog, you will find a clear, data-backed comparison of India and China as hand tool manufacturing hubs. It is not only focused on wages but also on productivity, efficiency, and overall long-term sourcing value, which is what buyers in B2B need to make decisions on.

Global Hand Tools Manufacturing Landscape in 2026

According to industry and market reports, the global hand tools industry is expected to maintain a steady growth trajectory in 2026. This growth is being supported by rising demand from construction and infrastructure projects, automotive maintenance, industrial repair activities, and the continued expansion of the DIY segment across global markets.

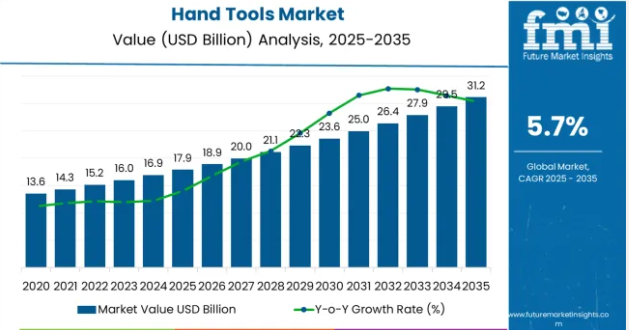

According to reported market projections, the global hand tools market is valued at USD 17.9 billion in 2026. It is expected to grow to USD 31.2 billion by 2035, registering a compound annual growth rate (CAGR) of 5.7% over the forecast period. This data indicates a sustained increase in hand tool consumption across both professional and consumer end-use segments.

Source: https://www.futuremarketinsights.com/reports/hand-tools-market

As per the market data, the market demand is dominated by core hand tools. Wrenches comprise almost 25.9% of the overall market for hand tools. Talking about market demand by the end-use industry, DIY projects currently dominate with a market share of 30.9%, indicating a rising trend in the adoption of self-repair and self-improvement tools.

Key Market Highlights (as per reported data)

- Hand Tools Market Value in 2025: USD 17.9 billion

- Forecast Market Value by 2035: USD 31.2 billion

- Projected CAGR (2025–2035): 5.7%

- Leading product segment: Wrenches (25.9% market share)

- Largest end-use segment: DIY applications (30.9% share)

As per industry analysis, this consistent market expansion is placing increased pressure on manufacturers to scale production while maintaining cost efficiency. For you as a buyer, this makes the choice of manufacturing location increasingly critical. Countries that can support higher production volumes without sharp increases in labor and operational costs are better positioned to offer stable pricing and dependable supply over the long term.

In this context, reported market trends show that global buyers are paying closer attention to labor-intensive manufacturing hubs that combine workforce availability, cost control, and production scalability—factors that directly influence sourcing decisions in a growing hand tools market.

Why Labor Cost Matters in Hand Tools Manufacturing

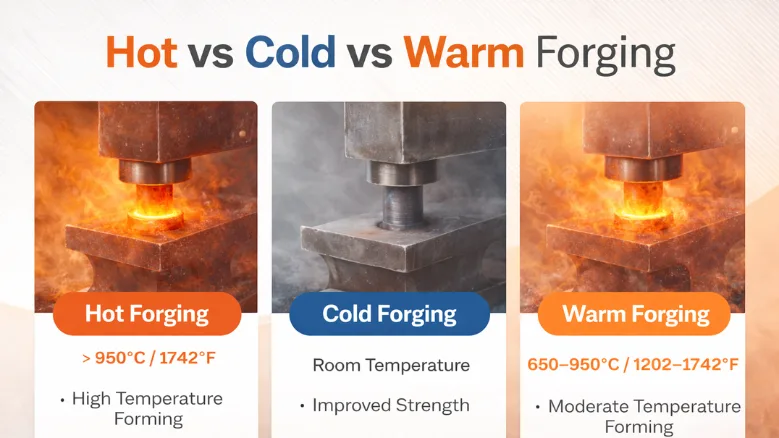

Hand tools are not completely automatic in their manufacturing process, not even today. Tasks like drop forging, machining, grinding, polishing, electroplating, assembling, and inspecting are still largely done manually.

According to the Niti Aayog Report, the labor cost contributes about 15% to the overall production cost in the hand tools industries. This indicates that the labor cost directly affects:

- Your product pricing

- Supplier Margins

- Ability to negotiate long-term contracts

- Total sourcing competitiveness

If you are purchasing in volume or planning private-label manufacturing, even a small differential in hourly labor costs can easily add up to a huge advantage.

Average Manufacturing Labor Cost: India vs China 2026

When you compare the average manufacturing labor cost in India and China in 2026, the difference is clear and measurable.

Labor Cost in India

India continues to provide one of the most competitive labor cost structures among major manufacturing economies.

- The average cost of labor for manufacturing in India is USD 1 per hour

- Large availability of semi-skilled and skilled workers

- Strong presence of clusters for manufacturing hand tools

- Moderate growth in wages compared to global peers

This results in a low cost per hour of labor, thereby giving them a natural cost advantage, especially in the labor-intensive segments of hand tools.

Labor Cost in China

China still is a very capable manufacturing base, but the labor costs have gradually increased over the years.

- The average labour cost of manufacturing in China is USD 3.5 per hour.

- More statutory benefits and compliance costs

- Labor shortages in the particular manufacturing hub

- The shift is toward higher-value and automated manufacturing.

While productivity stays high, the cost differential between China and India is substantial today, especially when labor is 15% of all production costs.

What This Cost Difference Means for You

To put it simply:

- If labor is USD 1/hour in India

- And USD 3.5/hour in China

Then, the cost of production in China could be more than three times higher in labor costs. This can make a difference directly to your landed cost, margins, and pricing competitiveness in world markets if you are producing high-volume hand tools.

Productivity, Skill Level & Manufacturing Efficiency

Labor cost does not tell it all. From a buyer’s perspective, one should consider productivity and skills level and manufacturing efficiency.

India’s Strengths

India’s hand tool industry is also gaining from the country’s vast experience in metalworking and forging, which spans decades.

Key advantages include

- Strong experience in drop forging and hand finishing

- Skilled manpower trained in traditional and modern methods of manufacture.

- High flexibility for customization, packaging changes, and batch variations

- Cost-effective balance between manual skill and automation

This will mean that, for you, Indian suppliers often do well in:

- Private-label manufacturing

- Custom specifications

- Diversified portfolios of products

China’s Strengths

China continues to lead in:

- Automation-driven consistency

- High-speed standardized production

- Large-scale manufacturing setups

Higher labor and operational costs mean Chinese factories are often better suited for:

- Very large, standardized production runs

- Less customizing

- High Initial Order Volumes

Your sourcing decision depends on whether you want flexibility with cost control or standardization at scale.

Beyond Labor Cost: Other Factors That Influence Sourcing Decisions

Experienced B2B buyers know that sourcing decisions are never based on labor cost alone. Several other factors influence total value and long-term reliability.

Raw Material Availability

India has a strong domestic steel industry, which supports steady access to raw materials used in hand tool manufacturing. This helps manufacturers manage supply risks and price volatility.

Quality Standards and Compliance

Global buyers increasingly require compliance with international standards such as DIN, ANSI, and GS. Export-oriented Indian manufacturers are aligning production, testing, and inspection processes to meet these requirements.

Logistics and Supply Chain Risk

With rising geopolitical uncertainty and freight disruptions, many buyers are looking to diversify sourcing beyond a single country. India’s growing export infrastructure supports this shift.

Communication and Responsiveness

Clear communication, faster decision-making, and flexibility in negotiations are often cited as strengths when working with Indian suppliers—especially for long-term B2B partnerships.

Why Many Global Buyers Are Shifting Hand Tools Manufacturing to India

The hand tools manufacturing business has been witnessing tremendous growth. The move to India is not based on lowest costs alone. It has been facilitated by a mix of structural and strategic drivers. Here are some important factors for consumers opting for purchasing from India:

- Labor cost advantage

- Large and Scalable Workforce

- Growing manufacturing maturity

- Export-focused production mindset

- Enhancing quality control and certification

- Improved risk diversification in international sourcing

JCBL Hand Tools, an Indian domestic manufacturer, demonstrates how export-friendly plants can achieve cost-effectiveness and meet international standards for product quality, thus making India a credible source for the long term.

Choosing the Right Hand Tools Manufacturing Partner

Even within the same country, hand tool manufacturers can differ significantly in capability, reliability, and long-term value. Careful selection of the right hand tool supplier for your business is one of the key considerations to make when ensuring that the quality and prices you get for the products that you require are optimal. The following are the considerations to make when choosing the right hand tool supplier:

- Manufacturing capacity and scalability: It needs to be evaluated whether or not the manufacturer will be able to meet your current levels of demand and increase production to meet any rise in demand without affecting lead time and quality.

- Quality consistency across production batches: Quality uniformity between all batches is a basic requirement. You need to examine the quality control processes employed by the supplier to ensure there are no disparities and failed batches.

- Certification and testing capabilities: Verifying that the manufacturer meets global certification criteria like DIN, ANSI, or GS specifications, or whether there are on-site or contract labs available for test verification.

- Experience with international buyers: Suppliers with past experience with international buyers would be more equipped to tackle export paperwork, packaging requirements, norms of compliance, and communication standards.

- After-sales support and issue resolution process: It is important that you are aware of how your supplier addresses any complaint or problem, since good after-sales service is essential for building and sustaining customer loyalty and confidence.

Having a well-structured evaluation process for supplier assessment can assist you in mitigating risks associated with sourcing, ensuring supply reliability, and making long-term partnerships for manufacturing, and not just short-term ones.

Conclusion

In 2026, the average labor cost for the manufacture of labor-intensive hand tools in the India vs. China comparison clearly indicates the superiority of the Indian labor cost. As labor contributes 15% to the production cost, the Indian labor cost of $1 per hour is significantly lower compared to the Chinese labor cost of $3.5 per hour.

With the thrust of a growing global market, improvement in manufacturing standards, and readiness for export, the coming decade has Australia favorably positioned as a strategic hand tool manufacturing destination.

If you are looking for trustworthy, export-friendly hand tool manufacturing in India, JCBL Hand Tools can help international consumers through its certified manufacturing, quality-oriented practices, and sourcing partnerships.

FAQs

- What is the average manufacturing labor cost in India vs China in 2026?

As per industry and government-backed reports, India’s average manufacturing labor cost is around USD 1 per hour, while China’s is approximately USD 3.5 per hour in 2026.

- Why does labor cost matter so much in hand tools manufacturing?

According to hand tool sector data, labor accounts for nearly 15% of total production costs in hand tools manufacturing, directly affecting product pricing, margins, and long-term sourcing competitiveness.

- Is India a cost-effective alternative to China for hand tools manufacturing?

Yes, as per reported market data, India offers a significant labor cost advantage, making it a cost-effective option for labor-intensive hand tools such as wrenches, pliers, and striking tools.

- Does lower labor cost in India impact hand tools quality?

No. Many Indian manufacturers supplying export markets follow international standards and quality control systems, ensuring product consistency despite lower labor costs.

- What should buyers consider besides labor cost when choosing a hand tools manufacturer?

You should also evaluate quality consistency, certifications, manufacturing capacity, export experience, and after-sales support to ensure reliable and long-term sourcing.