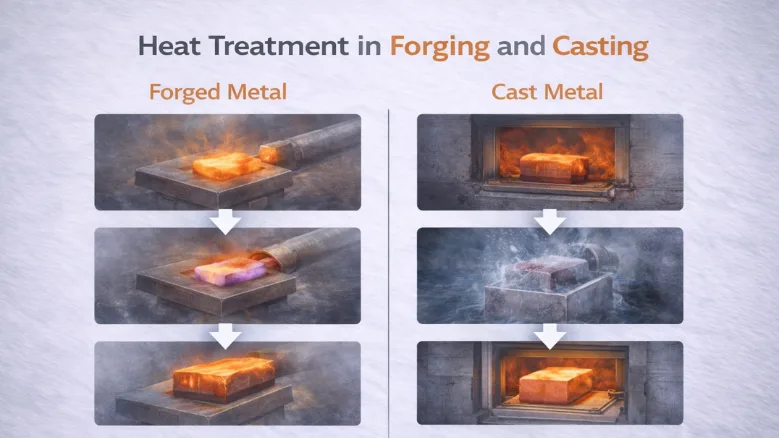

Heat Treatment in Forging and Casting: Process, Benefits

Heat treatment forging and heat treatment casting are controlled heating and cooling processes used to enhance the strength, hardness, toughness, and durability of metal components after shaping. These processes optimize the internal microstructure of metals, ensuring industrial tools perform safely and reliably under high stress and repeated use.

In metal manufacturing, heat treatment is a critical step performed after the forging process or the casting process. While forging and casting shape the metal, heat treatment defines its final mechanical performance.

What Is Heat Treatment in Metal Manufacturing?

Heat treatment is a metallurgical process where metal is heated to a specific temperature, held for a controlled duration, and cooled at a precise rate to modify its internal structure without changing its shape.

Why Is Heat Treatment Necessary?

During manufacturing, metals develop internal stresses and uneven grain structures. Heat treatment corrects these issues by refining the microstructure.

For carbon and alloy steels commonly used in tools:

- Heating typically occurs between 750°C to 950°C (depending on grade).

- Rapid quenching transforms the structure into martensite, increasing hardness.

- Tempering reduces brittleness while maintaining strength.

Common Heat Treatment Methods

- Hardening: Increases hardness and strength

- Tempering: Reduces brittleness after hardening

- Annealing: Improves ductility and relieves internal stress

- Normalizing: Refines grain structure and improves uniformity

Proper heat treatment directly improves:

- Tensile strength

- Impact resistance

- Surface hardness (often measured on the Rockwell scale)

- Fatigue life

For professional tool manufacturers, this step determines whether a tool lasts years or fails prematurely.

Heat Treatment in Forged Components

During the forging process, metal is shaped under high compressive forces, aligning the grain flow and improving structural strength. However, forged components still require heat treatment forging to achieve their final mechanical properties.

Why Heat Treatment Is Required After Forging

After forging, components may:

- Retain residual stresses from deformation

- Have uneven hardness distribution

- Lack sufficient wear resistance

Heat treatment forging helps:

- Increase hardness (often reaching 45–60 HRC depending on application)

- Improve impact resistance

- Enhance fatigue strength

- Stabilize the microstructure

Typical Heat Treatment for Forged Tools

Forged hand tools such as spanners, hammers, and pliers commonly undergo:

- Hardening to increase surface strength

- Tempering to reduce brittleness

- Controlled cooling to prevent cracking

For example, a forged spanner hardened without proper tempering may crack under torque. Controlled tempering balances hardness and toughness, ensuring safety during heavy-duty use.

Heat Treatment in Cast Components

In the casting process, molten metal solidifies inside molds. Unlike forging, casting may result in:

- Coarse grain structure

- Internal porosity

- Segregation

- Residual stress from uneven cooling

This is where heat treatment casting becomes essential.

Why Heat Treatment Is Used in Casting

Heat treatment casting improves:

- Structural uniformity

- Ductility

- Stress distribution

- Machinability

- Cast steel parts often undergo:

- Annealing to relieve stress

- Normalizing to refine grain structure

- Stress-relief cycles to reduce distortion

Unlike forged components, cast components focus more on structural refinement than grain alignment.

Key Differences: Heat Treatment in Forging vs Casting

Heat treatment forging primarily enhances hardness and mechanical strength, while heat treatment casting improves internal structure, reduces stress, and refines grain uniformity.

| Factor | Forged Components | Cast Components |

| Primary Objective | Increase hardness & strength | Improve structural uniformity |

| Grain Structure | Already aligned due to forging | Needs refinement |

| Common Methods | Hardening & tempering | Annealing & normalizing |

| Stress Levels | Stress from deformation | Stress from solidification |

In simple terms:

- Forged parts need heat treatment to maximize mechanical strength.

- Cast parts need heat treatment to improve internal structure and reduce defects.

Both processes are essential for ensuring tool reliability.

Why Heat Treatment Matters for Hand Tools

For hand tools, heat treatment directly affects performance and safety.

- Extends Tool Life: Heat-treated tools can last 2–3 times longer under repetitive load compared to untreated components.

- Improves Impact Resistance: Tempered steel absorbs shock without cracking.

- Enhances Wear Resistance: Higher surface hardness reduces rounding and deformation.

- Improves User Safety: Over-hardened tools may shatter; under-hardened tools may bend. Controlled heat treatment ensures balance.

At JCBL Hand Tools, heat treatment is performed under strict temperature control to ensure every tool delivers industrial-grade performance and reliability.

Industry Standards and Quality Control in Heat Treatment

To ensure consistent quality, heat treatment must follow strict process control and testing procedures.

Controlled Parameters

- Digital furnace temperature monitoring (±5°C accuracy)

- Controlled soaking time

- Regulated quenching media

- Calibrated thermocouples

Testing & Verification

After heat treatment, tools undergo:

- Rockwell Hardness Testing (HRC verification)

- Microstructure analysis

- Tensile strength testing

- Impact resistance testing

Reputed manufacturers follow recognized standards such as:

- ISO 9001 – Quality Management Systems

- ASTM material standards

- Applicable IS standards for industrial tools

Batch traceability and documented inspection ensure consistent mechanical properties across production lots.

Expert Insight: Inconsistent heat treatment can cause micro-cracks, distortion, or sudden tool failure. Precision temperature control and post-treatment hardness verification are essential to ensure structural reliability and worker safety.

Conclusion: Why Heat Treatment Is Critical in Tool Manufacturing

Heat treatment forging and heat treatment casting are essential stages in manufacturing durable, safe, and high-performance tools. Forged components depend on controlled heat treatment to achieve optimal hardness, strength, and toughness, while cast components rely on it to refine grain structure, reduce internal stress, and improve structural stability.

For hand tools, proper heat treatment directly impacts wear resistance, impact performance, and long-term reliability. A tool that is correctly hardened and tempered performs consistently under heavy loads and demanding working conditions.

Ultimately, the quality of heat treatment matters as much as material selection. Manufacturers that follow controlled temperature cycles, hardness verification, and industry standards ensure better safety, durability, and product value.

To explore precision-engineered tools manufactured with scientifically controlled heat treatment processes, visit JCBL Hand Tools.

FAQs

Heat treatment in forging and casting is a controlled heating and cooling process used to improve strength, hardness, and durability of metal components after they are shaped.

Heat treatment is required after forging to relieve internal stresses, increase hardness, improve toughness, and achieve desired mechanical properties.

Yes, heat treatment is commonly used in cast components to refine grain structure, reduce residual stress, and enhance mechanical strength.

Heat treatment increases wear resistance, improves impact strength, and prevents premature failure, significantly extending tool lifespan.

Most industrial-grade forged and cast tools undergo heat treatment. However, the method and intensity depend on the material and intended application.