The Complete Process of Hand Tool Manufacturing: From Forging to Finishing

Hand tools may look simple—wrenches, pliers, hammers, screwdrivers—but behind their simplicity lies a highly engineered and precision-controlled manufacturing process. Every high-quality tool goes through a series of carefully monitored stages, beginning with raw steel and culminating in a product strong enough to withstand impact, torque, pressure, and daily wear.

In global industries, from automotive workshops to construction sites, professionals rely on handworking tools that are reliable, durable, and safe. Understanding how these tools are made offers a deeper appreciation of their performance and helps buyers and distributors evaluate manufacturers more effectively.

This detailed guide walks through the complete process of manufacturing of tools, spotlighting how each step contributes to creating strong, long-lasting tools trusted worldwide.

Understanding What Makes a High-Quality Hand Tool

Before diving into the manufacturing journey, it’s important to understand what defines hand tools as premium-quality tools. Several key characteristics determine the value of a tool in real-world applications:

- Strength: Tools must withstand high torque, force, and repeated pressure without bending or breaking. This comes directly from the quality of steel used and the precision of forging and heat treatment.

- Durability: Long-lasting tools are those that resist corrosion, surface wear, and dimensional deformation. Strong coatings, high-grade materials, and proper finishing play a vital role here.

- Precision: Tools such as wrenches and pliers need exact jaw alignment and accurate dimensions to ensure safe and effective use. Machining and QC determine this.

- Ergonomics: A tool should feel comfortable and safe in the hand. Grips, balance, and smooth operation make a huge difference in daily usability.

- Consistency: What differentiates premium manufacturers from ordinary ones is consistency. Every piece in every lot must meet set tolerances and quality standards.

These traits are not accidental but the direct result of a robust, well-controlled manufacturing process.

Process of Hand Tool Manufacturing

Manufacturing of tools represents an integration of metallurgy, mechanical engineering, thermal science, and precision finishing. Each tool goes through its transformation from raw steel to a polished, ready-to-use product. The following is an in-depth look at each stage.

Stage 1: Choosing the Right Steel

The manufacturing journey begins with the selection of the appropriate steel grade. The type of steel will determine how strong, hard, corrosion-resistant, and durable the final tool will be. Commonly used steels in hand tools include:

- High Carbon Steel: Used mainly in the manufacture of cutting tools, files, and chisels. Characterized by hardness.

- Alloy Steel: Provides high toughness and flexibility; used in wrenches, sockets, and hammers.

- Chrome-Vanadium (Cr-V): Very high class, very hard and high tensile material.

- Chrome-Molybdenum (Cr-Mo): Applied for impact tools that are under shock loads.

Why material selection is critical

- Does not break up under stress

- Hardness and shape are maintained during intensive use.

- Improves corrosion resistance

- Ensures long service life

That is, reliability of the tools starts from the material level.

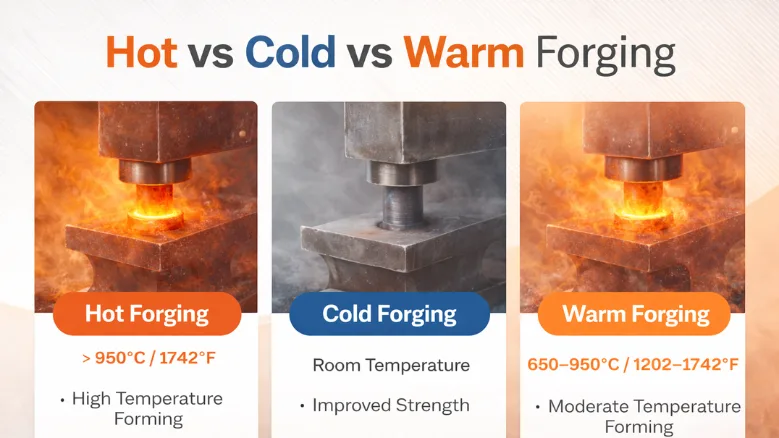

Stage 2: Forging—Where the Tool Gets Its Strength

Forging is one of the most important stages in making strong, professional-grade hand tools. During forging, steel billets are heated to high temperatures and shaped using large mechanical hammers or presses. Some of the advantages of forging include:

- Realigns the metal grain structure to be stronger.

- Hardens and gives resistance to impact.

- Improves longevity by reducing internal defects

- Better load-bearing capacity compared to cast or machined tools.

Forging is preferred over casting because cast tools are more prone to cracking, porosity, and structural weaknesses. Precision-forged tools are known for their superior performance and reliability.

Stage 3: Shaping & Refining the Tool

Once forged, the rough tool still carries excess metal and uneven surfaces. The shaping process gives the tool its final geometry and ensures accuracy. Key machining and shaping processes include:

- Trimming: This is a process involving the removal of superfluous metal, usually left during forging.

- Grinding: To produce fine surfaces and precision edges.

- Milling: The making of slots, openings or special profiles

- Drilling: for the holes, pivots, and/or fastening points

- Knurling or grooving: to impress gripping patterns onto handles.

- Threading: if it is to contain screws or attachments.

It transforms a roughly forged piece into tool form.

Stage 4: Heat Treatment—The Science Behind Tough Tools

Heat treatment is where the true mechanical properties of a tool are enhanced. Controlled heating and cooling manipulate the internal structure of the metal.

Common heat treatment processes:

Hardening: The tool is heated to a high temperature and then rapidly cooled to increase hardness.

Tempering: Reduces brittleness from hardening and improves flexibility and toughness.

Normalization refines grain structure and improves machining properties.

Why is heat treatment necessary

This ensures that the tool is able to resist torque without bending.

Provides the hardness for long-term wear.

Minimizes risk of cracking under stress.

Tools without proper heat treatment may look fine initially, but fail quickly in demanding environments.

Stage 5: Surface Coating & Anti-Corrosion Protection

Surface treatment protects tools from moisture, chemicals, wear, and impact. It also improves appearance and sometimes enhances grip. Common coatings include:

- Chrome plating: Very corrosion-resistant, aesthetic

- Nickel plating: Smooth finish; good wear resistance

- Black oxide coating: Anti-rust matte finish

- Powder coating: Thick, resistant layer for striking tools

- Satin finish: Anti-slip surface for superior grip

Coatings also allow tools to look professionally fresh even after several years of usage.

Stage 6: Assembly & Ergonomic Fine-Tuning

Not all tools are single-piece constructions. Items such as pliers, vices, greasing tools, screwdrivers, and some automotive tools require multi-component assembly. Activities in the assembly stage:

- Handles or grips attachment

- Fitting jaws, springs, and moving parts

- Riveting, or screwing

- Joints greasing

- Alignment of moving parts for smooth movement

This stage makes the tool work comfortably, safely, and efficiently.

Stage 7: Quality Testing

Quality is not an afterthought—it is woven throughout the process. Before tools reach the packaging stage, they undergo strict testing. Common tests include:

- Torque testing of wrenches and sockets.

- Hardness testing according to Rockwell or Vickers scales

- Measuring Dimensional Accuracy by Gauges

- Drop and impact tests for striking tools

- Coating thickness and tests of corrosion

- Vise-Grip and wrench load tests

Importers and end-users rely on consistent quality, making QC one of the most crucial steps in the entire process.

Stage 8: Final Touches—Branding, Polishing & Export-Grade Packaging

After each tool has passed quality checks, it gets its finishing touches. Final touches include:

- Polishing: It provides a clean, professional look.

- Laser marking: mainly for branding, size markings, and identification.

- Deburring: Sharp edges are removed to prevent user injury.

- Application of protective oil or coating

- Packaging: Blister packs, boxes or industrial export cartons.

The export-grade packing ensures protection against moisture, shocks, and long-distance transport damage.

Why This Manufacturing Process Matters

This is important for many reasons—whether one is a professional using these tools daily or an importer sourcing for international markets.

- Predictable performance: A well-manufactured tool performs predictably, without sudden failures.

- Safety: Better metallurgy, heat treatment, and precision prevent snapping, slipping, or cracking, which are key issues in industrial settings.

- Longer Life Span: The tools are of high quality and withstand years of usage, thereby reducing replacement costs.

- Better ROI for Importers: Distributors benefit due to less defects, better customer satisfaction, and better market reputation.

- Reliability Across Batches: Manufacturers that strictly follow production steps guarantee uniformity across every lot shipment.

A tool is only as good as the process behind it—and premium manufacturers rely on scientific, repeatable, globally accepted methods.

Conclusion

Hand tool manufacturing represents a mix of engineering, craftsmanship, and quality assurance. From choosing the right steel to forging, machining, heat treatment, coating, assembly, and final polishing, each step shapes the performance and longevity of the final tool. The process makes the tool either last for months or years, bend at the slightest stress or bear numerous heavy loads, and become the trusted companion of professionals the world over.

Selecting a manufacturer with a robust process is the key to finding reliable sourcing partners for distributors and importers.

JCBL Hand Tools is one of the trusted names in India, catering to global markets with advanced machinery, precision forging, a wide product range, and export-ready QC systems and packaging standards.

If you are looking for a reliable partner for bulk sourcing of high-quality hand tools, JCBL Hand Tools offers the manufacturing excellence that importers expect.

Discover the full range, or connect today to discuss your requirements.

FAQs

- What are hand tools?

Hand tools are manually operated instruments used in tightening, cutting, shaping, gripping, measuring, or striking tasks. To define hand tools simply, they are tools powered by human effort rather than by electricity or motors. Examples include wrenches, pliers, hammers, screwdrivers, and chisels.

- What are examples of common handworking tools?

Common handworking tools include spanners, combination wrenches, pliers, pincers, screwdrivers, vices, hammers, chisels, punches, and various carpentry or automotive tools. These tools find wide use in industries ranging from construction and repairs to agriculture and heavy metalwork.

- How does the manufacturing of tools impact their quality?

Manufacturing tools has a direct effect on strength, durability, and safety. The selection of steel, forging, machining, heat treatment, coating, and quality testing all tell whether the tool can bear real-world use without bending, breaking, or corroding.

- Why is forging an important part of the manufacturing of hand tools?

Forging is an important process because it aligns the internal grain structure of the metal, making tools tougher and stronger. Most professional-grade handworking tools are forged because the forging process gives the tool superior load-carrying capacity and a longer service life compared to cast or machine-only tools.

- How can buyers identify high-quality hand tools?

Tools should be finished properly, have accurate dimensions, wear corrosion-resistant coatings, be of ergonomic design, and possess a solid forged structure. Understanding how tools are made helps buyers assess whether a tool is constructed to international quality standards.