What is ODM Manufacturing?

ODM manufacturing is a very popular manufacturing model in the global industry arena. This model enables a business entity to market their product under their own label without having to design it. Under this approach, product design and development are the responsibility of the manufacturer, with the buyer concentrating on product branding, distribution, and marketing. This type of product manufacturing is most apparent where product standardization is necessary and the number of sales is high.

In the field of hand tools, manufacturing by ODM helps in launching ready-made tools to businesses in an efficient manner by incurring less technological as well as financial risk.

What Does ODM Mean in Manufacturing?

ODM stands for Original Design Manufacturer. In manufacturing terms, ODM refers to a business arrangement where:

- The owner of the product design is the manufacturer

- The buyer chooses an existing design

- The merchandise is marketed bearing the consumer’s brand name

The intellectual property, technical drawings, and engineering in general are owned by the manufacturer. There is limited room for modifications in purchasing, but customization for branding and packaging for marketing purposes can be done. This approach does not apply to OEM manufacturing, where the buyer supplies the product designs.

How ODM Manufacturing Works in the Hand Tool Industry

The production of ODM in the hand tool industry is carried out through a systematic, standardized, and reproducible process, which enables companies to import pre-designed tools.

Product Design and Development

It is actually this process by which a hand tool manufacturer creates designs for their tools by evaluating market demand, use, industry standards and regulations, safety requirements, and materials and durability to create a marketable product.

Product Selection

Branded products, distribution companies, or importers choose appropriate hand tools from an already existing product line that contains standardized designs proven for functionality, quality, and regulatory standards.

Branding and Minor Customization

Private labeling and limited cosmetic changes (such as brand logos, packaging format, surface finish, color, and product marking) can be applied by buyers while leaving the core design and functionality unchanged.

Manufacturing and Quality Control

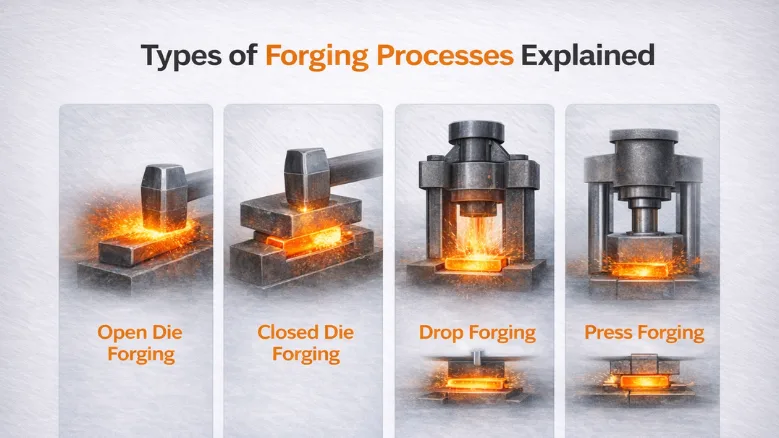

Hand tools are manufactured by established processes such as forging, machining, heat treatment, surface finishing, and assembly, with routine inspections to ensure quality and dimensional accuracy.

Packaging and Distribution

Finished tools are packed according to buyers’ specifications, which might include either retail or bulk packaging, prepared for domestic distribution or international shipping, and complete with appropriate documentation.

This streamlined process for ODM helps the business shorten development timelines, simplify sourcing, and reduce operational complexity while maintaining consistent product quality.

Common Hand Tools Produced Under ODM Models

ODM manufacturing is well-suited to hand tools that have standardized functions and specifications. General examples include:

- Spanners and wrench sets

- Hammers and striking tools

- Pliers and gripping tools

- General-purpose toolkits

These tools can often satisfy the most common and widely accepted industry standards, and therefore ODM production is suitable to target a wide range of markets.

Key Characteristics of ODM Manufacturing

ODM Manufacturing is defined by several key traits that specify how a product is to be made and distributed to B2B purchase clients.

Manufacturer-Owned Designs

It is the responsibility of the manufacturer to develop designs for the products using technical drawings created by them, with a view to using the same design template for different brands.

Ready-to-Market Products

Products are developed in an anticipatory manner and are always ready for production, which immediately helps businesses get started without having to wait for product development and design validation.

Limited Design Customization

Customization is limited to non-structural aspects, such as branding, color schemes, or packaging, and the basic product size, material, and functionality will remain the same.

Private Labeling Capability

ODM manufacturers enable the buyer to market the products under their own brands by designing unique logos, labels, packaging, and products, all without spending a single penny for ownership.

Scalable Production Volumes

The manufacturers are supportive of flexible order quantities and allow buyers to produce according to market demand without having to invest capital in manufacturing infrastructure and tools.

Standardized Quality and Specifications

Products are produced with similar materials, processes, and inspection criteria, thereby ensuring similar quality and similar results are achieved despite different production and market batches.

Such properties make ODM manufacturing an efficient choice for businesses that favor speed, cost management, and easy handling over unique designs of their end product.

Benefits of ODM Manufacturing for B2B Buyers

ODM manufacturing makes the following advantages possible for B2B buyers in the hand tool industry, especially for companies that value speed, cost, and ease of doing business:

Reduced Development Cost

ODM manufacturing eliminates the need for product design, engineering, prototyping, or testing within a company, thus lowering investment costs for product development management.

Faster Time to Market

Because product designs are already finalized, manufacturing can begin quickly, allowing businesses to respond faster to market demand and shorten product launch timelines.

Reduced Technical Risk

ODM products are usually based on established and previously manufactured designs, lowering the risk of performance failures, quality issues, or design-related production challenges.

Simplified Supply Chain

Existing tooling, materials, and manufacturing processes streamline sourcing, production planning, and supplier coordination, helping businesses manage operations more efficiently.

Easier Product Line Expansion

ODM manufacturing allows companies to add new hand tools or tool categories without expanding internal engineering teams or investing in additional technical resources.

Limitations and Considerations of ODM Manufacturing

Despite its advantages, ODM manufacturing also presents certain limitations that businesses should carefully evaluate.

- Limited Design Control: Buyers typically have little influence over core product design, materials, and functionality, which may restrict innovation or product differentiation.

- Reduced Product Exclusivity: The same product designs may be supplied to multiple buyers, limiting exclusivity and increasing the likelihood of similar products appearing across competing brands.

- Competitive Overlap: Since differentiation is largely based on branding, pricing, and distribution strategy, businesses may face direct competition with similar-looking products in the market.

- Dependence on Manufacturer: Product upgrades, design improvements, and technical changes depend on the manufacturer’s development priorities and timelines rather than the buyer’s internal strategy.

Understanding both the benefits and limitations of ODM manufacturing helps B2B buyers choose a manufacturing model that aligns with their long-term business goals and market positioning.

Who Should Choose ODM Manufacturing?

ODM manufacturing is suitable for:

- Startups entering the hand tool market

- Distributors and wholesalers creating private-label brands

- Retail-focused businesses need fast product availability

- Companies testing new markets or product categories

- Businesses with limited R&D resources

It is ideal for organizations prioritizing speed, cost control, and operational simplicity.

ODM vs OEM Manufacturing: Key Differences

People often get confused over the ODM and OEM, but they serve different business needs.

In ODM manufacturing, the manufacturer designs and produces the product, and the buyer brands and sells it. In OEM manufacturing, the buyer owns the design and provides detailed specifications, while the manufacturer focuses only on production.

ODM is best for businesses seeking faster launches and lower costs, while OEM is better for companies needing full design control and product exclusivity.

Conclusion

ODM manufacturing is a crucial part of the hand tools industry and is used by companies to provide their customers with market-ready solutions efficiently and swiftly. ODM manufacturing further eliminates development costs and is useful in growing and scaling their business, especially in challenging and cost-sensitive markets.

Enterprises considering their options for manufacturing should weigh their prospects for success under an ODM or OEM business model.

FAQs

- What does ODM stand for in manufacturing?

ODM stands for Original Design Manufacturer. This refers to when a company designs and produces products for sale under a different company’s brand.

- Is ODM manufacturing suitable for B2B businesses?

Yes, ODM manufacturing is quite common in B2B purchases such as those made by distributors, wholesalers, and retailers.

- Can ODM products be customized?

It is generally only involved in terms of branding, packaging, and cosmetic modifications.

- How is ODM different from OEM manufacturing?

ODM uses designs owned by the manufacturer, while the OEM manufacturing process involves the production of goods based on buyer-sent designs.

- Is ODM manufacturing scalable?

Yes, ODM manufacturing can be scaled for large production.