Anvils are a fundamental tool in various metalworking processes, from traditional blacksmithing to modern fabrication. These robust tools provide a stable surface for hammering, shaping, and cutting metals. This comprehensive guide explores what anvils are, their history, and the different types available today.

What is an Anvil?

An anvil is a heavy, usually steel, block with a flat top surface on which metals are hammered and shaped. The anvil’s mass and hardness provide the necessary resistance to shape metals effectively. Traditionally used by blacksmiths, anvils remain crucial in metalworking shops, hobbyist setups, and industrial manufacturing.

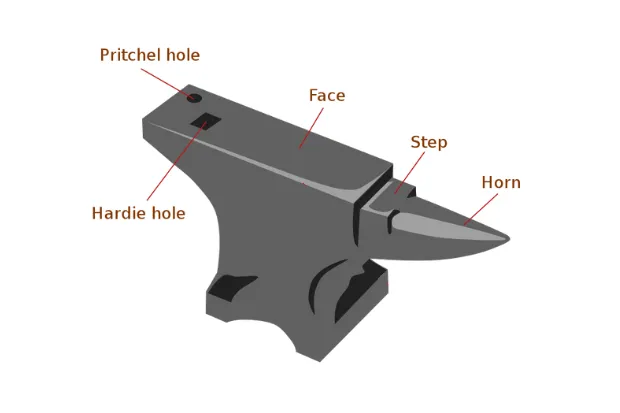

Key Components of an Anvil

- Face: The flat top surface where most of the work is performed.

- Horn: A rounded projection used for bending and shaping metal.

- Step: A small, flat area between the face and the horn, often used for cutting.

- Hardie Hole: A square hole for holding hardy tools (specialized tools like chisels or cutting tools).

- Pritchel Hole: A round hole used for punching and bending rods.

Types of Anvils

There are several types of anvils, each designed for specific applications. Understanding the different types of anvils can help you choose the right one for your needs.

1. Blacksmith Anvils

Blacksmith anvils are the most common type of anvil, traditionally used in forging and blacksmithing These types of anvils are versatile and robust, making them suitable for a wide range of metalworking tasks. The large face provides ample space for striking and shaping metals, while the horn is essential for creating curves and bends. The Hardie hole accommodates tools like chisels and cutters, increasing the anvil’s functionality. The pritchel hole is useful for punching holes in metal, making these anvils ideal for blacksmiths who need a multi-purpose tool for different forging processes.

Key Features:

- A large, flat face for general hammering.

- A horn for bending and shaping metal.

- Hardie and Pritchel holes for tool insertion and metalworking operations.

Uses: Ideal for general blacksmithing, metal forging, and shaping tasks.

2. Farrier Anvils

Farrier anvils are tailored to the specific needs of farriers who must shape and fit horseshoes accurately. The narrower face provides better control and precision, which is crucial when working on horseshoes. The specialized horns help bend and shape the metal to fit the unique contours of a horse’s hoof. These anvils are often lighter and more portable, allowing farriers to take them to different locations, such as stables or farms, making them highly practical for mobile use.

Key Features:

- Narrower face compared to blacksmith anvils for easier maneuverability.

- Specialized horns for shaping horseshoes.

- Often lighter and more portable.

Uses: Best suited for shaping and fitting horseshoes, and other farrier tasks.

3. Bench Anvils

Bench anvils are ideal for tasks that require fine detailed work and precision. Their compact size and lightweight design make them easy to handle and mount on workbenches. Many bench anvils come with multiple faces, each tailored for different tasks such as flattening, bending, or shaping small pieces of metal. Including clamps or mounts ensures stability during use, preventing the anvil from shifting while you work. These anvils are perfect for jewelers, small-scale metalworkers, and hobbyists who need a reliable and versatile tool for intricate metalworking projects.

Key Features:

- Compact and lightweight.

- It can have multiple faces for different tasks.

- Often includes clamps or mounts for stability.

Uses: Ideal for small-scale metalworking, jewelry making, and detailed work.

4. Jeweler’s Anvils

Jeweler’s anvils are specifically designed for the fine, detailed work required in jewelry making and other delicate metal crafts. Their small size and lightweight nature make them easy to use for precision tasks. The smooth, polished surfaces of these anvils ensure that precious metals are not scratched or damaged during the shaping process. Multiple shapes and faces on the anvil allow jewelers to perform a variety of tasks, from flattening and shaping to bending and texturing, making them indispensable in any jewelry workshop.

Key Features:

- Very small and lightweight.

- Smooth, polished surfaces for working with precious metals.

- Can have multiple shapes and faces for intricate work.

Uses: Perfect for jewelry making, fine metal crafting, and other precision tasks.

5. Stake Anvils

Stake anvils are versatile and portable tools that can be securely mounted by driving their spiked base into a workbench, tree stump, or other solid surfaces. They come in various shapes and sizes, each designed for specific metalworking tasks such as bending, shaping, or forming. Their portability makes them ideal for mobile workstations or fieldwork where a stable surface is needed but a traditional anvil is impractical. Stake anvils are commonly used by artisans and metalworkers who require flexibility and adaptability in their tools.

Key Features:

- The spiked base for secure mounting.

- Various shapes and sizes for different applications.

- Portable and versatile.

Uses: Useful for mobile workstations, fieldwork, and applications where portability is essential.

6. Double Horn Anvils

Double horn anvils are designed to offer maximum versatility for metalworkers. The two horns—one rounded and one tapered—provide different shaping options, making it easier to create various curves and angles in the metal. The large flat face offers ample space for general hammering and forging tasks. Additionally, the hardie and pritchel holes increase the functionality of the anvil by allowing the use of a wide range of hardy tools and for punching operations. These anvils are well-suited for complex shaping tasks, blacksmithing, and decorative metalwork.

Key Features:

- Two horns for increased versatility.

- Large flat face for general hammering.

- Often includes hardie and pritchel holes.

Uses: Suitable for complex shaping tasks, blacksmithing, and decorative metalwork.

7. Colonial Anvils

Colonial anvils are designed to replicate the historic anvils used in past centuries. They are often used for restoration projects, historical reenactments, and traditional blacksmithing. These anvils feature a large, flat face suitable for general metalworking and forging tasks, along with a single horn for basic shaping. The design and construction of colonial anvils reflect traditional craftsmanship, and they may include decorative elements that add to their historic appeal. These anvils are perfect for blacksmiths and metalworkers who value traditional tools and methods.

Key Features:

- Historic design and construction.

- Large, flat face with a single horn.

- Often includes decorative elements.

Uses: Ideal for restoration projects, historical reenactments, and traditional blacksmithing.

Choosing the Right Anvil

When selecting an anvil, consider the following factors:

- Weight: Heavier anvils provide more stability but are less portable.

- Material: Steel anvils are more durable and resistant to wear compared to cast iron.

- Design: Choose an anvil design that matches your specific metalworking needs.

Conclusion

Anvils are essential tools in metalworking, offering a stable surface for shaping and forming metal. Understanding the different types of anvils can help you select the right one for your tasks, whether you’re a blacksmith, farrier, jeweler, or hobbyist. When choosing an anvil, consider reputable manufacturers such as JCBL Hand Tools, known for their quality and craftsmanship. Invest in a quality anvil that suits your needs to enhance your metalworking projects and ensure precision and durability in your work.