The hammer has been a fundamental striking tool since the beginning of human civilization, helping with everything from basic home repairs to complex construction projects. Understanding the various types of hammers and how they work can help you work more effectively and efficiently. A right hammer is an essential component of any industry’s toolkit, whether it is for carefully setting tiles, shaping metal, or driving nails into hardwood floors.

Why Are There Different Types of Hammers?

Different types of hammers are designed to meet the specific needs of various tasks. Factors such as the material being worked on, the type of work (e.g., demolition, construction, metalworking), and the need for precision versus power all influence hammer design. Specialized hammers improve efficiency and safety by providing the right tool for the job.

Material Compatibility: The force and precision needed to work with different materials varies. For example, a sledgehammer is made for heavy-duty operations like cracking concrete, whereas a soft-faced hammer is used for delicate materials to prevent damage.

Task Specificity: Some tasks require a particular kind of hammer. A ball peen hammer is best used for metalworking activities like riveting, whereas a claw hammer is best used for light prying and nail driving.

Safety and ergonomics: Hammers are designed to minimize operator fatigue and boost security. Hammers’ ergonomic grips and handles differ depending on how long and how hard they are used.

Accuracy and Precision: Some certain tasks require a high degree of precision, hammers with improved control for precise work, such as framing hammers or tack hammers, have been developed.

Technological Advancements: Tools change along with industries. In order to fulfill modern demands, new materials and design methods resulted in the development of more effective, long-lasting, and specialized hammers.

10 Basic Types of Hammer

Each hammer is designed for specific tasks. Here’s a detailed look at some common types of hammers and their applications.

Claw and Framing Hammers

The claw hammer is one of the most versatile and commonly used hammers. It features a flat striking surface on one side, perfect for driving nails into various materials with precision and force. On the other side, the hammer has a curved claw that is specifically designed for pulling nails out of wood or other surfaces, making it incredibly useful for both construction and demolition tasks. This dual functionality makes the claw hammer an essential tool for general carpentry, household repairs, and even minor demolition tasks, where both driving and removing nails are frequently required.

Ball Peen Hammer

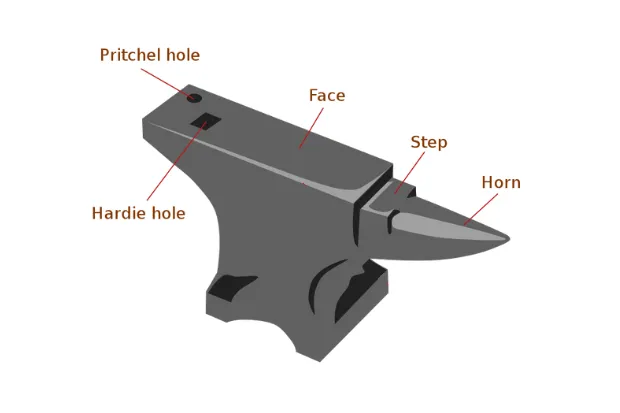

The ball peen hammer is a specialized tool primarily used in metalworking. It is also known as a machinist’s hammer. It features a flat face for striking and hammering and a rounded peen on the opposite side. This rounded peen is used for shaping and expanding metal, making it ideal for tasks like riveting and metal fabrication. This hammer is commonly used in blacksmithing, sheet metal work, and other metalworking applications where shaping and modifying metal parts are required.

Sledge Hammer

A sledgehammer is a powerful tool with a large, heavy head and a long handle, designed for delivering maximum force. It is often used in heavy-duty tasks such as demolition, where significant impact force is required to break through concrete, masonry, or other tough materials. The long handle allows for a two-handed grip, providing the leverage needed to generate powerful swings. Sledgehammers are essential for construction and demolition work, particularly when breaking up concrete slabs, driving stakes into the ground, or performing tasks that require substantial force.

Rubber Mallets

The rubber mallet is designed for tasks that require a softer touch, ensuring that surfaces are not damaged during use. It has a soft, rubber head that delivers gentle strikes, making it ideal for assembling furniture, positioning tiles, or working with wood and sheet metal. Unlike metal hammers, a rubber mallet won’t mar or dent surfaces, making it perfect for delicate projects. The lightweight and ergonomic design of the rubber mallet allows for easy handling and precise control. This hammer is particularly useful in woodworking and auto body repair, where maintaining the integrity of the material is crucial.

Dead Blow Hammer

A dead blow hammer is a specialized tool designed to minimize rebound and deliver controlled powerful strikes. The head of the hammer is filled with sand or steel shot, which absorbs the shock and prevents the hammer from bouncing back after impact. This makes it ideal for tasks that require precise control and minimal surface damage, such as automotive repair, woodworking, and metalworking. The dead blow hammer is particularly useful when striking objects that need to remain in place, as the lack of rebound reduces the risk of damaging the workpiece or the surrounding area.

Tack Hammer

Also known as an upholstery hammer, the tack hammer is a small, lightweight tool specifically designed for delicate tasks. It features a split head with one side magnetic, allowing it to hold small tacks or brads in place for easy positioning. This makes it perfect for upholstery work, where precision and control are essential. The tack hammer is also used in detailed woodworking and other crafts that require driving small fasteners without damaging the surrounding material. Its lightweight design and ergonomic handle provide excellent maneuverability and reduce user fatigue during extended use.

Cross Peen Hammer

The cross peen hammer is characterized by its unique design, featuring a wedge-shaped peen perpendicular to the handle. This makes it an essential tool for blacksmiths and metalworkers, as the wedge shape is perfect for shaping and bending metal. The flat face on the opposite side is used for general striking and hammering tasks. This dual functionality allows for a wide range of metalworking applications, including forging, riveting, and bending metal rods or sheets. The cross peen hammer is also useful in woodworking for creating joints and detailed work.

Club Hammer

Club hammer also known as a lump hammer. The club hammer is a compact, heavy-duty tool with a short handle and a double-faced head. It is used for delivering powerful strikes in tight spaces where a full-sized sledgehammer would be impractical. The club hammer is perfect for light demolition tasks, driving chisels and masonry nails, and breaking small concrete slabs. Its compact size allows for precise control, making it suitable for tasks that require both force and accuracy. The head is typically made of hardened steel, ensuring durability, while the handle is often constructed from wood or fiberglass to provide a comfortable grip and absorb shock during use.

Brick Hammer

The brick hammer, also known as a masonry hammer, is designed specifically for working with bricks, stones, and masonry materials. It features a flat face on one side for striking and setting bricks and a chisel-like blade on the other side for cutting and shaping them. This dual-purpose design makes the brick hammer an essential tool for masons and construction workers. The chisel blade is perfect for trimming bricks to size, while the flat face can be used to tap them into place.

Engineer’s Hammer

The engineer’s hammer, also known as a heavy-duty sledgehammer, is a robust tool designed for tasks that require significant force. It features a heavy head and a long handle, similar to a sledgehammer but usually smaller in size. This makes it ideal for metal fabrication, driving stakes and posts, and demolition work.

The engineer’s hammer is commonly used in construction, mining, and industrial applications where powerful, controlled strikes are necessary. The handle, often made from wood or fiberglass, ensures a secure grip and effective shock absorption, allowing for prolonged use without excessive strain on the user. This hammer is essential for heavy-duty tasks that require precision and strength.

Factors to Consider in a Hammer

When choosing a hammer, consider the following factors to ensure you select the right tool for your needs:

- Purpose: Identify the primary use of the hammer to choose the appropriate type.

- Weight: The weight of the hammer head affects the force of the strike and user fatigue.

- Handle Length: Longer handles provide more leverage, while shorter handles offer better control in tight spaces.

- Material: The material of the hammer head and handle can impact durability and comfort.

- Face Texture: Smooth faces are less likely to mar surfaces, while milled faces provide better grip on nails.

Proper Maintenance of Hammers

Regular inspections are the first step in caring for various types of hammers. You can identify when it’s time to replace or repair the hammer head by looking for chips, cracks, or other wear indicators. A hammer’s capacity to strike can be compromised by a twisted neck, so pay close attention to it. Furthermore, examine the handle, searching for indications of degradation or weakening. Over time, wooden handles are especially prone to splintering, which could cause a dangerous loss of control. By being watchful and taking care of any problems as soon as they arise, you can ensure that your hammer is always prepared for the job at hand

Conclusion

Selecting the right hammer for your project is essential for efficiency, safety, and the quality of your work. Understanding the various types of hammers and their specific uses can help you make informed decisions and enhance your productivity. Proper maintenance ensures your tools remain in top condition, ready for any task you undertake. Whether you’re a professional tradesperson or a DIY enthusiast, having the right hammer for the job can make all the difference.

When choosing a hammer, consider reputable manufacturers such as JCBL Hand Tools, known for their quality and craftsmanship. Invest in a quality hammer that suits your needs to enhance your projects and ensure precision and durability in your work.

FAQs

How many different hammers are there?

There are many different types of hammers—estimates range from dozens to over a hundred—each made for specific industries and tasks.

What is the strongest type of hammer?

The sledgehammer is usually considered the strongest type of hammer, made to deliver heavy blows in construction and demolition.

What is the most common hammer?

The most common type of hammer is the claw hammer, which is used extensively for minor prying, driving nails, and general carpentry.

What’s the big hammer called?

A sledgehammer refers to a large hammer that is typically employed for high-duty activities. It is known for its large, flat head and heavy, long grip.

What is a soft hammer called?

A soft hammer is often called a mallet, often has a rubber, wooden, or plastic head that allows it to strike objects gently without causing damage.

What is a round head hammer called?

A round-head hammer is commonly known as a ball peen hammer, used in metalworking for riveting and shaping metal.