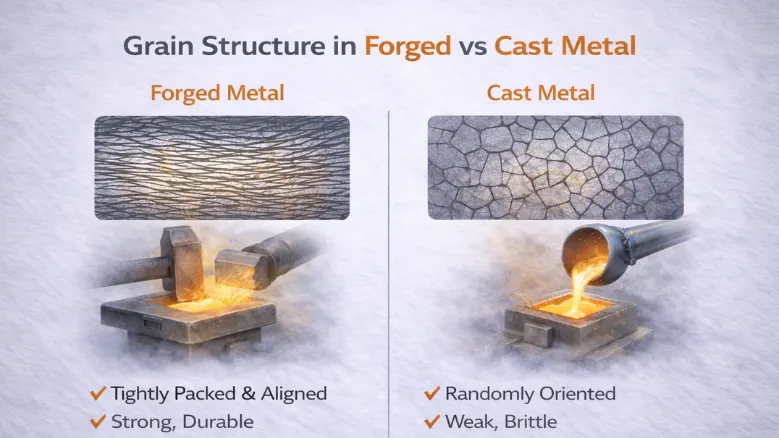

Grain Structure in Forged vs Cast Metal

Grain structure in forged vs cast metal differs in grain alignment, density, and internal integrity. Forged metal develops compressed, directional grain flow that enhances strength, fatigue resistance, and impact performance. Cast metal forms random grain patterns during solidification, which can create stress concentration points and reduce durability. This microstructural difference directly determines tool reliability under load.

Understanding grain structure forging principles helps explain why forged metal strength is superior in demanding applications.

What Is Grain Structure in Metal?

Grain structure refers to the microscopic arrangement of crystals (grains) inside metal. When metal solidifies or undergoes deformation, atoms organize into crystalline patterns called grains. The size, orientation, and alignment of these grains directly influence:

- Tensile strength

- Impact resistance

- Fatigue life

- Crack propagation

- Structural reliability

Metals are not solid masses internally; they are made of millions of tiny crystal grains joined together. The way these grains form or align determines whether a tool bends, cracks, or withstands heavy force.

In manufacturing, grain structure is controlled through processes like forging, rolling, casting, and heat treatment. During high-temperature deformation, processes like recrystallization refine grain size, further enhancing fatigue resistance and structural stability.

Grain Structure in Forged Metal

In forging, metal is heated to a plastic state (not melted) and shaped under compressive force. This mechanical deformation causes the internal grains to:

- Elongate

- Align in the direction of force

- Compact tightly together

This process creates grain flow.

Why Grain Structure Forging Increases Strength

When metal is forged, compressive force reshapes its internal crystal structure rather than melting it. This deformation causes grains to elongate and align along the contour of the component, forming continuous grain flow.

In metallurgical analysis, this aligned grain structure improves tensile strength and fatigue resistance because applied stress distributes along grain boundaries instead of concentrating at isolated weak points. The result is reduced crack initiation and a slower crack propagation path.

This directional grain alignment also produces anisotropic strength, meaning the metal performs exceptionally well along the direction of applied force. Through controlled deformation mechanics, forging eliminates internal voids and increases structural density.

As a result, forged components demonstrate:

- Higher impact resistance

- Improved fatigue life

- Reduced stress concentration

- Greater structural reliability under torque and shock loads

This is the core reason forged vs cast metal strength differs so significantly in demanding industrial applications.

If you’ve read our guide on forged vs cast, you’ll notice that structural integrity always favors forged components when grain flow alignment is required.

Grain Structure in Cast Metal

Casting involves melting metal completely and pouring it into a mold. As the molten metal cools and solidifies, grains form naturally without mechanical alignment.

This results in:

- Random grain orientation

- Larger grain size

- Possible internal porosity

- Inconsistent structural density

Because no compressive force shapes the grains, there is no directional grain flow. Under microscopic examination, forged metal displays elongated grains flowing along the contour of the component, forming continuous grain lines. Cast metal, in contrast, shows equiaxed grains with random orientation and occasional micro-voids formed during solidification.

How Cooling Affects Grain Structure

During solidification:

- Outer layers cool first

- Inner material solidifies later

- Shrinkage may create microscopic voids

These microstructural inconsistencies can act as stress concentration points, reducing overall strength.

While casting allows complex shapes, its grain structure does not offer the same impact resistance as forged material.

Why Grain Structure Affects Tool Strength

Grain structure directly determines how the metal handles:

- Shock loads

- Repeated stress cycles

- Bending forces

- Sudden impact

1. Crack Resistance

In forged metal, aligned grains slow crack propagation. Meanwhile, in cast metal, random grain boundaries create stress concentration zones, allowing cracks to follow an easier crack propagation path compared to forged metal.

2. Impact Resistance

Forged metal absorbs and redistributes force because compressed grains are tightly packed. This improves impact resistance, one of the key hot forging advantages in industrial tool manufacturing.

3. Fatigue Life

Repeated loading weakens metal over time. Forged components resist fatigue better due to uniform grain flow.

4. Structural Reliability

Forged tools maintain strength even under torque, vibration, and mechanical shock. Cast components are better suited for low-impact structural roles.

Forged vs Cast Metal Strength: How Grain Structure Makes the Difference

| Property | Forged Metal | Cast Metal |

| Grain Orientation | Aligned (grain flow) | Random |

| Density | High | Moderate |

| Porosity | Minimal | Possible |

| Crack Resistance | High | Moderate |

| Impact Resistance | Excellent | Lower |

| Fatigue Strength | Superior | Lower |

This difference in grain structure is the primary reason forged tools are preferred in automotive, industrial, and heavy-duty applications.

Conclusion

Grain structure is the hidden foundation of metal strength. While both forging and casting shape metal into usable forms, their internal crystal structures differ significantly. Forging compresses and aligns grains to create dense, durable, and impact-resistant tools. Casting forms metal through solidification, resulting in random grain patterns that may limit structural performance under heavy stress.

For applications where safety, torque, and repeated impact matter, grain flow alignment makes forged metal the stronger and more reliable choice.

FAQs

Grain structure refers to the microscopic crystal arrangement inside metal. The size, shape, and alignment of these grains determine strength, durability, and resistance to cracking.

Forged metal is stronger because the compressive force aligns and compacts grains, creating directional grain flow that improves impact resistance and fatigue strength.

Yes. Casting produces random grain orientation during cooling, which may result in larger grains and internal porosity compared to forged metal.

Yes. Grain flow improves resistance to cracking, bending, and impact, making it essential for high-performance tools.

Yes. Forging compresses grains tightly together, allowing the metal to absorb and redistribute impact forces more effectively than cast metal.