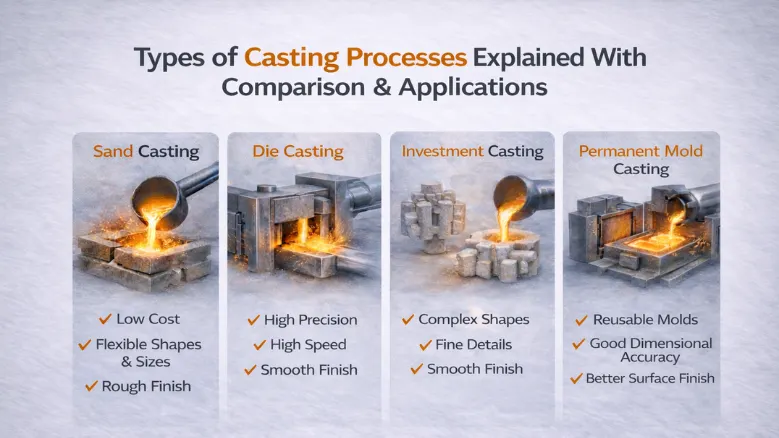

Types of Casting Processes Explained With Comparison & Applications

Mainly, there are four types of casting processes, including sand casting, die casting, investment casting, and permanent mold casting. Each metal casting method differs in cost, accuracy, surface finish, and production volume, making it suitable for specific industrial applications.

Before delving deeper, read “What is Casting?” to better understand the

What Is Sand Casting?

Sand casting is a metal casting process where molten metal is poured into a sand mold to produce solid metal components. It is widely used for large, heavy-duty industrial parts.

How Sand Casting Works

- Pattern creation with shrinkage allowance

- Mold cavity preparation using a sand mixture

- Core placement (if internal cavities are required)

- Molten metal pouring into the mold

- Solidification and cooling

- Mold breakage and casting removal

- Cleaning and finishing operations

Advantages

- Low tooling and setup cost

- Suitable for large and heavy components

- Compatible with ferrous and non-ferrous alloys

- Flexible design modifications

Limitations

- Rough surface finish

- Moderate dimensional tolerance

- Higher risk of casting defects like porosity

Industrial Applications

- Engine blocks

- Pump housings

- Heavy machinery bases

- Tool bodies requiring structural mass

Best Materials

- Cast iron

- Aluminum alloys

- Bronze

- Steel

Sand casting remains the most widely used casting process due to its scalability and cost-effectiveness.

What Is Die Casting?

Die casting is a high-pressure casting process where molten non-ferrous metal is injected into hardened steel dies. It is ideal for high-volume production of precision components with tight tolerances.

How Die Casting Works

- Die preparation and lubrication

- Molten metal injection under high pressure

- Rapid solidification

- Ejection of casting

- Trimming and finishing

Advantages

- High-dimensional accuracy

- Smooth surface finish

- Excellent repeatability

- High production speed

Limitations

- High initial tooling cost

- Not suitable for very large parts

- Mostly limited to non-ferrous metals

Industrial Applications

- Automotive components

- Electrical enclosures

- Tool housings

- Consumer hardware

Best Materials

- Aluminum

- Zinc

- Magnesium

Die casting is preferred when strength, consistency, and high production volume are critical.

What Is Investment Casting?

Investment casting, also known as lost-wax casting, is a precision casting process used to manufacture intricate components with excellent surface finish and tight tolerances.

Advantages

- Superior dimensional precision

- Complex internal geometries are possible

- Minimal machining required

- Excellent surface quality

Limitations

- Higher production cost

- Longer manufacturing cycle

- Multi-step process

Industrial Applications

- Aerospace components

- Medical equipment parts

- Precision tool components

- Industrial fittings

Investment casting is one of the most accurate metal casting methods available for complex designs.

What Is Permanent Mold Casting?

Permanent mold casting uses reusable metal molds instead of sand molds. It provides better mechanical strength and surface finish compared to traditional sand casting.

Advantages

- Improved grain structure

- Better surface finish

- Higher mechanical properties

- Consistent production quality

Applications

- Automotive pistons

- Cylinder heads

- Industrial mechanical components

Limitations

- Higher tooling investment

- Limited design flexibility

- Not suitable for extremely complex shapes

Industrial Applications

- Automotive pistons

- Cylinder heads

- Medium-volume structural components

- Hand tool assemblies requiring repeat consistency

Permanent mold casting offers a balance between cost efficiency and precision.

Casting Process Comparison Table

| Casting Process | Tooling Cost | Accuracy | Surface Finish | Production Volume | Best For |

| Sand Casting | Low | Moderate | Rough | Low–Medium | Large heavy parts |

| Die Casting | High | High | Smooth | High | Mass production |

| Investment Casting | Medium–High | Very High | Excellent | Medium | Complex precision parts |

| Permanent Mold | Medium | High | Good | Medium | Repeated industrial runs |

This comparison highlights how different casting processes serve different manufacturing requirements.

How to Choose the Right Casting Process

Choosing the right casting process depends on:

- Production volume

- Required dimensional tolerance

- Surface finish expectations

- Mechanical strength requirements

- Alloy selection (ferrous vs non-ferrous)

- Budget constraints

Quick Selection Guide:

- For high-volume precision parts, choose die casting

- For large, heavy-duty components, choose sand casting

- For complex shapes with tight tolerances, choose investment casting

- For medium production with better strength, choose permanent mold casting

Manufacturers must also consider mold cavity design, solidification rate, shrinkage allowance, and potential casting defects such as porosity or cold shuts.

Selecting the appropriate metal casting method directly affects durability, wear resistance, and operational reliability.

Common Casting Defects and Quality Control

In metal casting, controlling defects is essential to ensure strength, durability, and structural integrity. The most common casting defects include:

- Porosity: Small gas voids trapped during solidification, which reduce strength and fatigue resistance.

- Shrinkage: Internal cavities caused by metal contraction during cooling due to improper feeding or riser design.

- Cold Shuts: Weak lines or cracks formed when two streams of molten metal fail to fuse properly.

To prevent these issues, manufacturers apply strict quality control measures.

Visual inspection is the first step, identifying surface cracks, misruns, and visible shrinkage before further processing.

Hardness testing verifies material strength, alloy composition, and heat treatment effectiveness, ensuring compliance with mechanical performance standards.

Effective defect control reflects advanced manufacturing expertise and ensures reliable, high-performance cast components.

Casting vs. Forging: What’s the Difference?

Casting and forging are both metal-forming processes but they differ in strength, cost, and structural characteristics. Here is the quick comparison of the difference between casting and forging:

| Feature | Casting | Forging |

| Process | Molten metal poured into mold | Metal shaped under compressive force |

| Strength | Moderate | Higher grain strength |

| Design Complexity | High | Limited compared to casting |

| Cost | Lower for complex shapes | Higher tooling but stronger parts |

Casting allows intricate shapes, while forging enhances grain alignment and mechanical strength. In the hand tools industry, both processes may be selected based on performance requirements.

Industries That Rely on Metal Casting

Industries that rely on metal casting include automotive, construction, aerospace, oil & gas, heavy equipment, and hand tool manufacturing.

In the hand tools sector, casting processes are used to manufacture tool bodies, housings, vices, clamps, and structural components where durability and impact resistance are critical.

With decades of manufacturing expertise, JCBL Hand Tools understands that casting process selection is not just a production step, it is a performance decision. Combining material science knowledge, precision engineering, and strict quality control ensures industrial-grade reliability and safety.

Selecting the Right Casting Process for Performance and Durability

Choosing the right casting process is essential for achieving strength, precision, and long-term durability. Sand casting works best for large components, die casting suits high-volume precision parts, investment casting delivers intricate geometries, and permanent mold casting provides consistent repeat production with improved mechanical properties.

The right decision impacts production efficiency, product lifespan, and compliance with industrial standards. For manufacturers in demanding sectors, casting selection directly influences tool strength, wear resistance, and structural integrity.

If you are seeking durable, industrial-grade hand tools engineered with the right manufacturing processes, explore the complete product range from JCBL Hand Tools or connect with the team to learn more about their manufacturing capabilities.

Frequently Asked Questions

The four main types of casting processes are sand casting, die casting, investment casting, and permanent mold casting.

Sand casting is the most commonly used method due to its low tooling cost and flexibility for large components.

Yes, die casting is suitable for certain non-ferrous tool components requiring precision and a smooth surface finish.

Common casting materials include cast iron, aluminum, steel, bronze, zinc, and magnesium alloys.

Casting is cost-effective for producing complex shapes and large components compared to machining solid metal blocks.

Yes. Incorrect activation, tampering, or using improper electrolyte can void the warranty.