Hot vs Cold vs Warm Forging: Key Differences Explained

In the manufacturing of professional hand tools, forging is not only a metalworking technique; it is also a critical parameter in determining the strength, durability, accuracy, and performance of the tool. For industrial buyers, OEM manufacturers, and procurement managers, it is essential to recognize the significance of forging temperature in determining these parameters in evaluating the quality of tools and the credibility of the supplier.

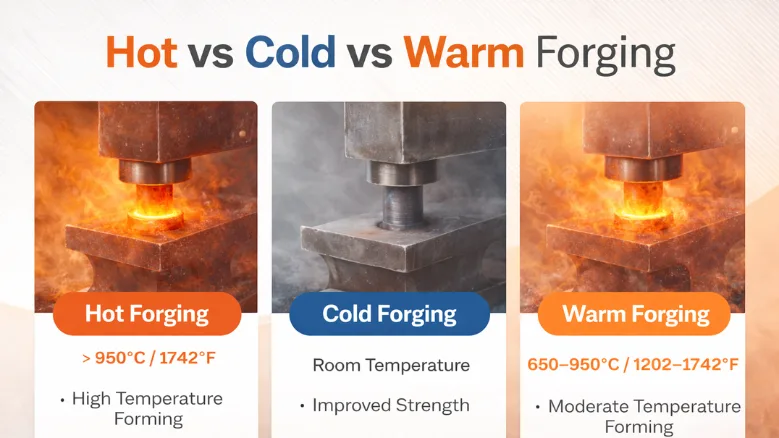

Among the various forging techniques, hot forging, cold forging, and warm forging are the most popular metal forming techniques used in metalworking. This blog post will give a detailed description of hot forging vs cold forging vs warm forging, describe the difference between hot and cold forging processes, and present a forging temperature comparison with special emphasis on industrial and professional hand tools.

Overview of Forging Temperature Methods

Forging is a metalworking process where metal is formed using compressive forces, usually through dies or hammering. Unlike casting, the internal grain structure of metal is refined in forging, making it stronger and more resistant to fatigue.

The basic categories of forging processes are temperature-dependent, which determines the ease of metal flow during the process:

- Hot forging is done above the recrystallization temperature of the metal.

- Cold forging is done at or near room temperature.

- Warm forging is done between the temperatures of hot and cold forging.

As the temperature rises, the metal becomes more ductile and easier to form, but less accurate. The opposite is true at lower temperatures. In the manufacturing of hand tools, the forging temperature is critical to ensure that the final tool meets the required performance, safety, and durability criteria.

Hot vs Cold vs Warm Forging: Strength, Accuracy, and Manufacturing Effect

To make a valid comparison between forging processes, it is necessary to compare all three processes simultaneously. By comparing all three processes, it is possible to understand the strengths and weaknesses of each process.

Hot Forging: Maximum Toughness and Structural Integrity

Hot forging is a type of forging in which the metal is heated to a temperature higher than its recrystallization temperature, which in the case of steel can be above 900°C. At such high temperatures, the metal is highly ductile and can be easily shaped into complex dies with less pressure.

The main advantage of hot forging is the alignment of the metal’s grain structure. During the forging process, the metal grain structure is aligned according to the die shape, resulting in a substantial increase in the impact resistance and strength of the metal. This makes hot forging a preferred process for making tools that are subjected to heavy loads, shock, and impact.

The important advantages of hot forging are:

- Maximum toughness and resistance to fatigue

- Minimum internal voids and defects

- Efficient thick or complex part forming

However, since the metal cools down after forging, there may be dimensional variations. Hence, hot-forged components often require secondary machining or finishing operations to achieve desired tolerances.

Cold Forging: Precision, Accuracy, and Surface Finish

Cold forging is done at or near room temperature. As metal is not heated, it becomes relatively harder to deform, and hence work hardening takes place in the process. This leads to the increased strength and hardness of the forged component.

The cold forging die possesses the following benefits:

- High degree of accuracy of dimensions

- Excellent surface finish

- Less material wastage

- Less post-processing

The above benefits of cold forging make it the best choice for precision hand tools, where accuracy of dimensions is of prime importance. But cold forging has the drawback of requiring significantly higher forces during the process. It is not suitable for thick-section or complex components.

Warm Forging: The Middle Ground

Warm forging is done at intermediate temperatures, which range from 600°C to 800°C. At this temperature, metal flow is better than cold forging, and accuracy of dimensions is better than hot forging.

The advantages of warm forging are:

- Better formability with lower forces of forming

- Better accuracy of dimensions than hot forging

- Better mechanical properties than cold forging

From the point of view of forging temperature, warm forging has the advantage of reduced tool wear and lower energy requirements compared to hot forging. Additionally, warm forging provides manufacturers with more flexibility to accommodate various design requirements.

Understanding the Difference Between Hot and Cold Forging in Context

The significance of the difference between hot and cold forging can be better understood when compared to warm forging. While hot forging focuses on strength and impact resistance, cold forging focuses on accuracy and surface finish. Warm forging, on the other hand, aptly combines both.

Why Warm Forging is Preferred as a Mid-Temperature Process

Warm forging is preferred as a mid-temperature process, not as a compromise but as a conscious choice when tools need to be strong as well as dimensionally stable. When the manufacturers are not fully satisfied with the result of either hot or cold forging, they turn to warm forging.

The temperature range of warm forging increases the plasticity of metals with less oxidation and scaling. This helps in easy control of the final size with desirable properties of grain. Furthermore, the force of formation is reduced compared to cold forging, and the dies have a longer life.

Warm forging is most useful for:

- Medium-duty hand tools

- Parts requiring controlled tolerances and strength

- Tools intended for varied industrial applications

By providing strength, precision, and process efficiency, warm forging plays a pivotal role in contemporary hand tool forging technology.

Which Forging Method Is Best for Hand Tools?

There is no “best” forging process for hand tools in general. The best forging process depends on the intended use of the tool, the stresses it will be subjected to, and the degree of accuracy required.

Heavy-Duty and Shock Tools

Tools subjected to shock loads or high torque requirements are best forged using the hot forging process. The properties of hot forging, such as the continuous flow of the grain structure, provide tools with long life and durability.

Examples include:

- Hammers and striking tools

- Heavy-duty spanners and wrenches

- Construction and infrastructure tools

- Precision and Close-Tolerance Tools

Cold forging is the best process where accuracy, precision, and surface finish are of utmost importance. These tools demand accurate interaction with fasteners and have to be accurate and repeatable on a large scale in production.

Examples include:

- Precision pliers

- Socket components

- Specialized fastening tools

- Multi-Purpose and Professional-Grade Tools

Warm forging is most appropriate for tools that need to be accurate as well as strong. Many professional hand tools belong to this category, where high performance is required.

In this way, the selection of the forging process is directly related to the intended use of the tool.

Choosing the Right Forging Process

Choosing the right forging process is a technical and strategic decision in manufacturing. Only experienced manufacturers assess several factors before making a final decision on the process. Here are some of the most critical factors to consider for the forging selection process:

- Tool Utilization: Load capacity, usage rate, and usage conditions

- Material Requirements: Carbon steel, alloy steel, or other materials

- Functional Specifications: Impact strength, durability, and accuracy

- Volume Production: Scalability and economy

- Post-Forging Processing: Heat treatment, machining, and finishing

Knowledge of “what is hot forging,” “what is cold forging,” and “what is warm forging” helps manufacturers correlate manufacturing processes with practical performance requirements. For B2B market buyers, it is essential to work with a manufacturer who has the ability to control the parameters of the forging process.

Conclusion

Knowledge of the differences between hot, cold, and warm forging is critical in understanding the performance of hand tools. Every forging temperature process has its own applications, and the process to be used is not dependent on economic factors but on the application. By using the correct forging process, tool manufacturers can offer tools that are of professional standards in terms of performance, accuracy, and durability.

FAQs

The difference between the three is the temperature involved. Hot forging is done at high temperatures, cold forging is done at room temperature with precision, and warm forging is done at intermediate temperatures where strength and precision are balanced. Hot forging is best for strength.

Hot forging provides the best impact strength because of the better alignment of the grain flow.

Cold forging offers the highest dimensional accuracy and surface finish, making it suitable for precision tool components.

Warm forging is better when both strength and dimensional control are required, but hot forging remains superior for tools exposed to extreme impact.

All three methods are used depending on tool design, hot forging for heavy tools, cold forging for precision components, and warm forging for balanced performance tools.