Lack of equipment is the main obstacle when it comes to working on vehicles, not a lack of patience or ignorance. The right tools can make all the difference in getting a task done efficiently and correctly.

However, if you’re stuck without them the chances are a small task becomes a lengthy task, the problem will get worse, or nothing will be fixed at all.

With the proper equipment in your toolbox, you can tackle a wide range of repairs and maintenance tasks without having to rely on expensive professional help.

Essential Automotive Tools

Here are 15 essential automotive tools that every DIY mechanic should consider adding to their collection:

1. Socket Set

A socket set typically includes a ratcheting handle and a variety of sockets in different sizes (both metric and standard). These sockets are designed to fit over nuts and bolts, allowing you to loosen or tighten them efficiently. Look for sets with both shallow and deep sockets for versatility.

2. Wrench Set

Wrenches come in various types, including combination wrenches (which have an open end and a closed end), adjustable wrenches, and specialty wrenches like flare nut wrenches or crow’s foot wrenches. They’re used for turning nuts and bolts in areas where a socket set might not fit.

3. Screwdriver Set

Screwdrivers are essential for removing or installing screws in various parts of your vehicle. Phillips head screwdrivers have a cross-shaped tip, while flathead screwdrivers have a single, flat tip. Having a range of sizes ensures you’ll have the right tool for the job.

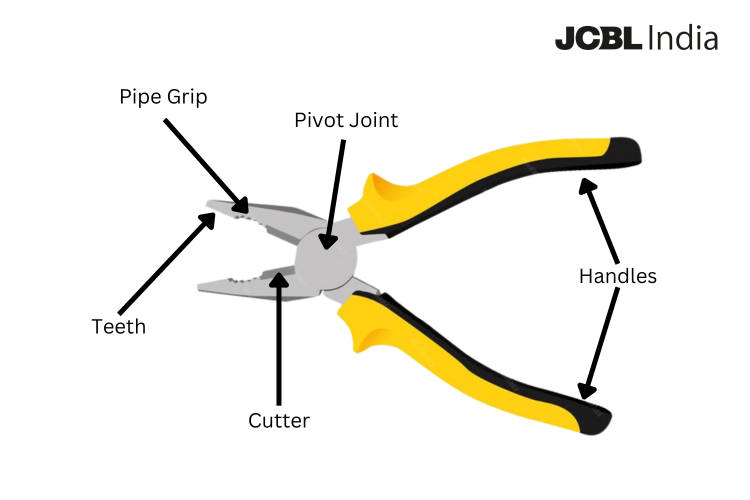

4. Pliers

Pliers are versatile tools that can grip, bend, cut, and hold objects. Slip-joint pliers have an adjustable jaw, needle-nose pliers have long, narrow jaws for reaching tight spaces, and locking pliers have a mechanism that allows them to clamp onto objects and hold them in place.

5. Jack and Jack Stands

A hydraulic floor jack is used to lift your vehicle off the ground for tasks like tire changes or undercarriage inspections. Jack stand provides stable support once the vehicle is lifted, ensuring safety while you work underneath it.

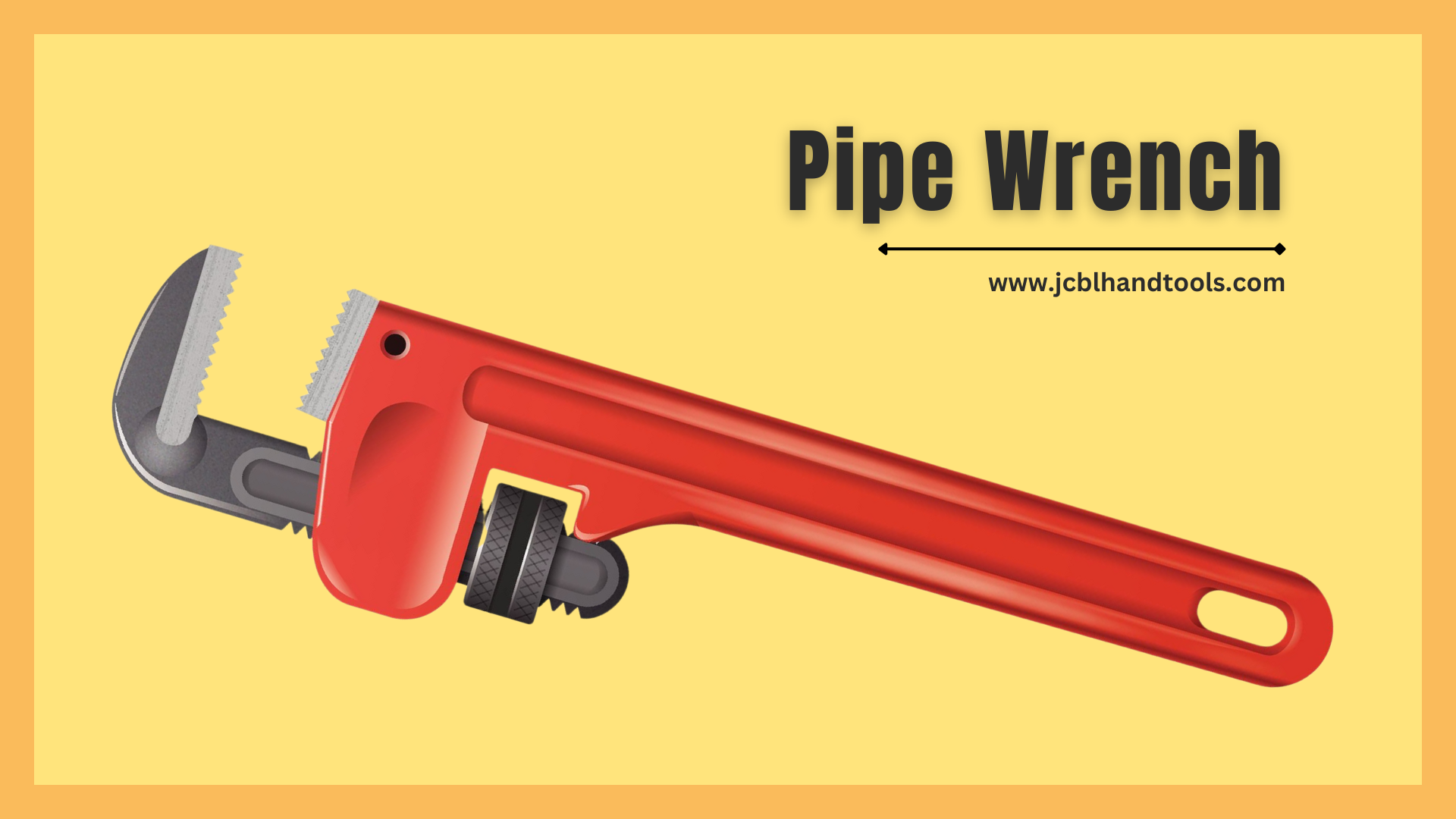

6. Oil Filter Wrench

An oil filter wrench tool is designed to grip and loosen the oil filter housing, making it easier to remove the oil filter during an oil change. Make sure to choose a wrench that matches the size and type of your oil filter.

7. Torque Wrench

Torque wrenches allow you to tighten bolts to a specific torque specification, ensuring they’re not too loose or too tight. This helps prevent overtightening, which can damage components, or under-tightening, which can lead to leaks or failure.

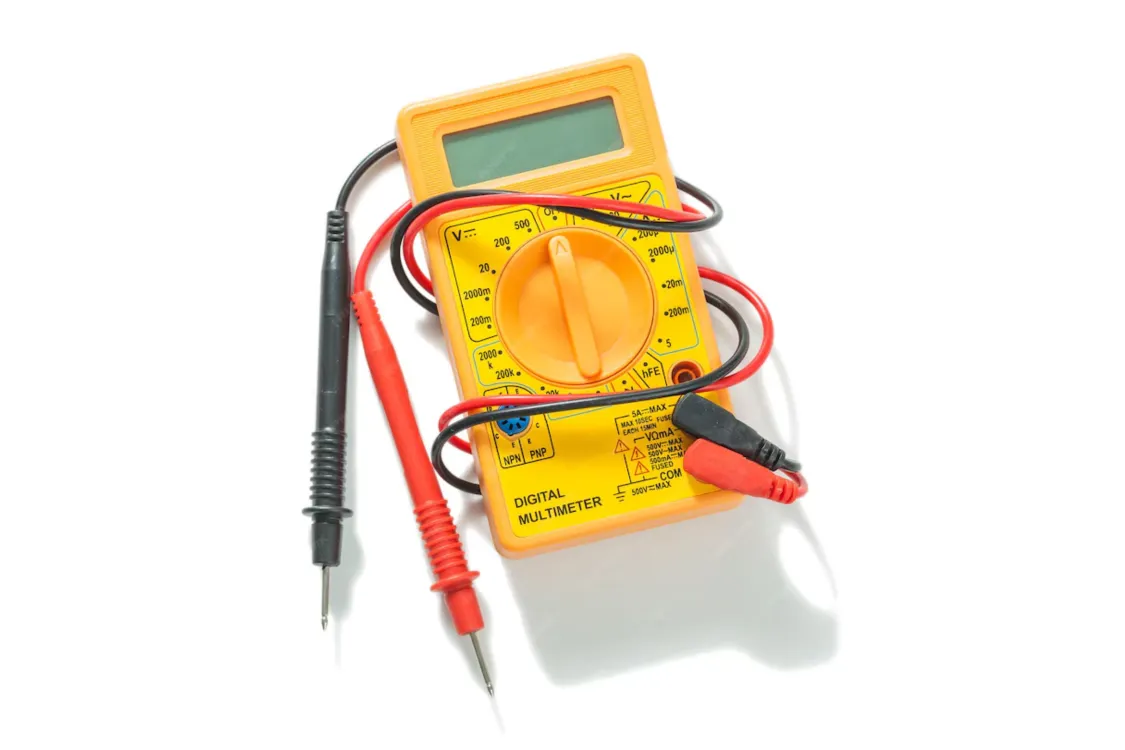

8. Multimeter

Multimeters measure various electrical properties like voltage, current, and resistance. They’re invaluable for diagnosing electrical issues in your vehicle, such as checking battery voltage, testing fuses, or troubleshooting wiring problems.

9. Brake Bleeder Kit

Brake bleeder kits include a pump or vacuum tool and hoses designed to remove air bubbles from your brake lines. Properly bleeding the brakes is crucial for maintaining brake performance and ensuring safety on the road.

10. Lug Wrench

Also known as a tire iron, a lug wrench is used to loosen and tighten the lug nuts that secure your vehicle’s wheels to the hub. It’s essential for changing a flat tire or removing wheels for maintenance.

11. Compression Tester

This tool measures the compression pressure in your engine’s cylinders. Low compression can indicate issues like worn piston rings or valves, allowing you to diagnose engine problems accurately.

12. Funnel Set

Funnels are used for pouring fluids like oil, coolant, or transmission fluid into your vehicle’s reservoirs without spilling. Having a set of funnels in different sizes ensures you can access various fill ports easily.

13. Rubber Mallet

Unlike a traditional metal hammer, a rubber mallet delivers a softer blow, making it ideal for tapping components into place or freeing stuck parts without damaging them.

14. Wire Brushes

Wire brushes are used for removing rust, corrosion, or dirt from metal surfaces. They’re handy for cleaning battery terminals, brake calipers, or any other metal components before maintenance or repair work.

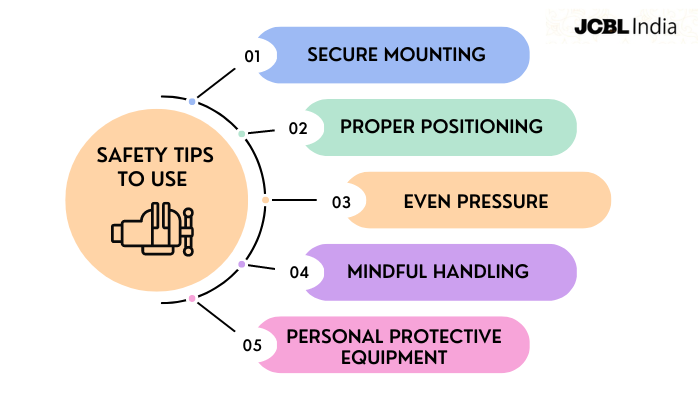

15. Safety Gear

Safety goggles protect your eyes from debris or fluids, work gloves provide hand protection from cuts or abrasions, and hearing protection reduces the risk of hearing damage from loud noises generated during automotive work. Always prioritize safety when working on your vehicle.

By equipping yourself with these essential automotive tools, you’ll be well-prepared to tackle a wide range of DIY maintenance and repair tasks on your vehicle. Remember always to prioritize safety and take your time to do the job right. With practice and the right tools, you can save time and money by handling your car maintenance yourself. Happy wrenching!