Category: General

Principais Fabricantes e Fornecedores de Ferramentas Manuais no BrasilPrincipais Fabricantes e Fornecedores de Ferramentas Manuais no Brasil

A JCBL Hand Tools é um dos mais confiáveis fabricantes de ferramentas manuais no Brasil, atuando como parceiro estratégico para importadores, distribuidores e atacadistas que buscam fornecimento industrial em grande [...]

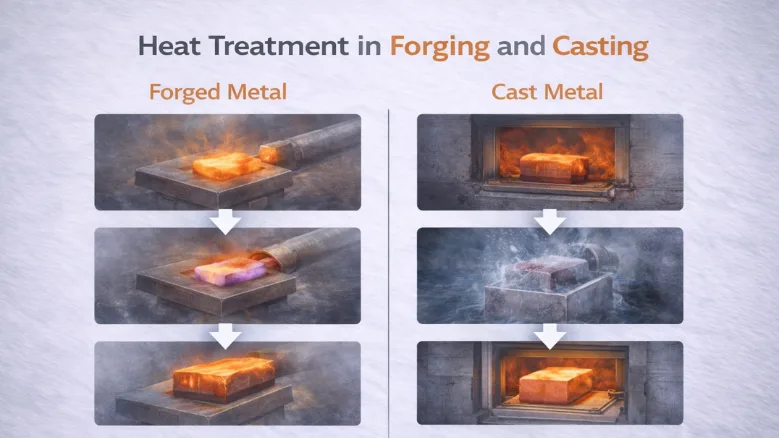

Heat Treatment in Forging and Casting: Process, BenefitsHeat Treatment in Forging and Casting: Process, Benefits

Heat treatment forging and heat treatment casting are controlled heating and cooling processes used to enhance the strength, hardness, toughness, and durability of metal components after shaping. These processes optimize [...]

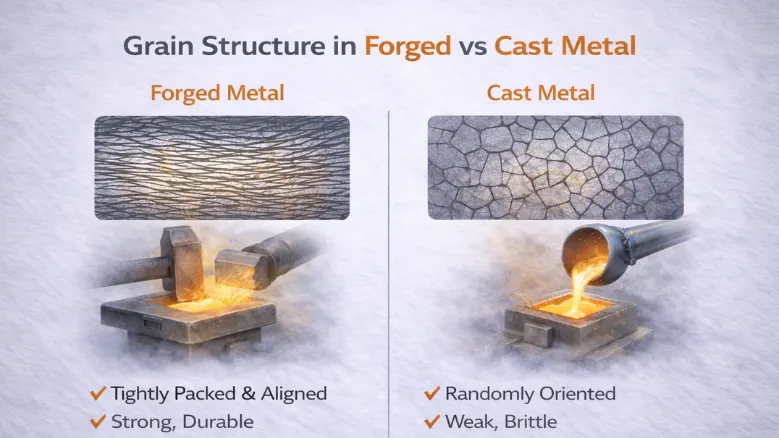

Grain Structure in Forged vs Cast MetalGrain Structure in Forged vs Cast Metal

Grain structure in forged vs cast metal differs in grain alignment, density, and internal integrity. Forged metal develops compressed, directional grain flow that enhances strength, fatigue resistance, and impact performance. [...]

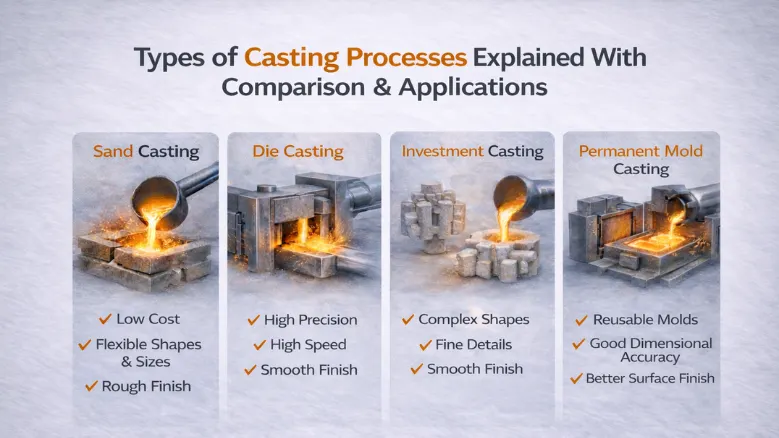

Types of Casting Processes Explained With Comparison & ApplicationsTypes of Casting Processes Explained With Comparison & Applications

Mainly, there are four types of casting processes, including sand casting, die casting, investment casting, and permanent mold casting. Each metal casting method differs in cost, accuracy, surface finish, and [...]

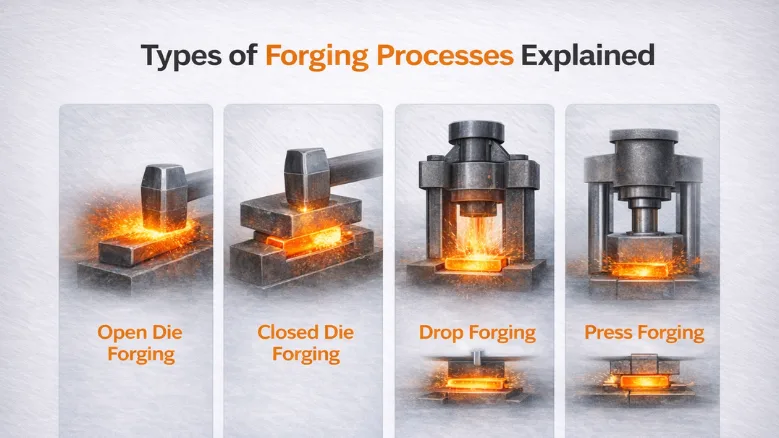

Types of Forging Processes ExplainedTypes of Forging Processes Explained

Types of Forging Processes Explained Forging processes are manufacturing processes used to create strength and durability in metal components that are pressed using compressive forces. In the manufacturing of hand [...]

What Is Warm Forging?What Is Warm Forging?

Warm forging is an advanced metal forming process that bridges the gap between cold forging and hot forging. It combines the dimensional accuracy of cold forging with the improved metal [...]

What Is Hot Forging?What Is Hot Forging?

In the world of industrial tool-making, strength and dependability are not optional items; they are necessities. For example, in the world of heavy loads, impacts, and harsh working conditions, tools [...]

What Is Cold Forging?What Is Cold Forging?

Cold forging is a well-used technique used in the development process that ensures the creation of precise components. Generally, cold forging differs from other forging technologies since the process does [...]

What is OEM Manufacturing ?What is OEM Manufacturing ?

OEM Manufacturing is a common method used in various industries worldwide where the manufacturer produces goods for another company to be sold using the latter’s brand name. OEM comes from [...]

What is ODM Manufacturing?What is ODM Manufacturing?

ODM manufacturing is a very popular manufacturing model in the global industry arena. This model enables a business entity to market their product under their own label without having to [...]

What Is Casting?What Is Casting?

Casting is one of the most established processes in the metalworking sector. Despite the developments in metalforming processes, casting has maintained its relevance in the manufacture of complex-geometry parts with [...]

What is Forging?What is Forging?

In manufacturing, forging is a proven metal-shaping method used to produce components that require high strength, durability, and reliability. The forging refers to the process in which the metal is [...]